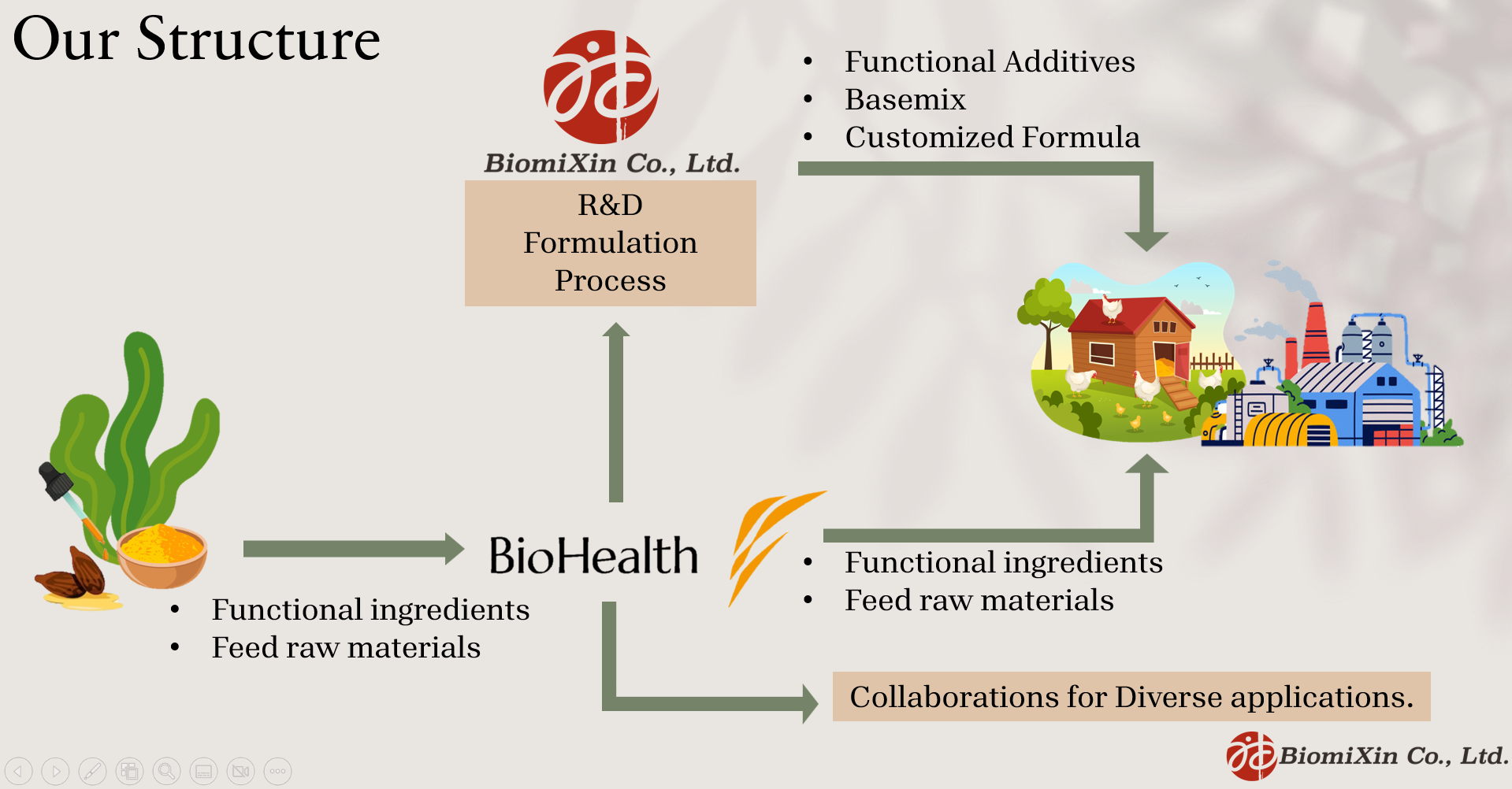

As a company with nearly two decades of experience as a premix manufacturer, BiomiXin is now expanding its expertise into ingredient trading. We have an in-house R&D team focused on developing high-quality ingredients, but we also source premium raw materials from external suppliers. Our dual position in the market – both as a manufacturer and a trader – gives us a distinct advantage. As a manufacturer, we understand the true needs of the market, ensuring we never compromise on quality. Our role as a trader enables us to bring these high-value materials to those who need them, while adding our own value through process innovation.

At BiomiXin, we consider ourselves a central hub for ingredient resources. Not only do we trade ingredients, but we also develop new formulas and continuously improve our own product lines. This approach benefits not only feed millers but also cultivators, who gain access to innovative solutions that improve their overall performance.

Our Methodology for Selecting Raw Materials

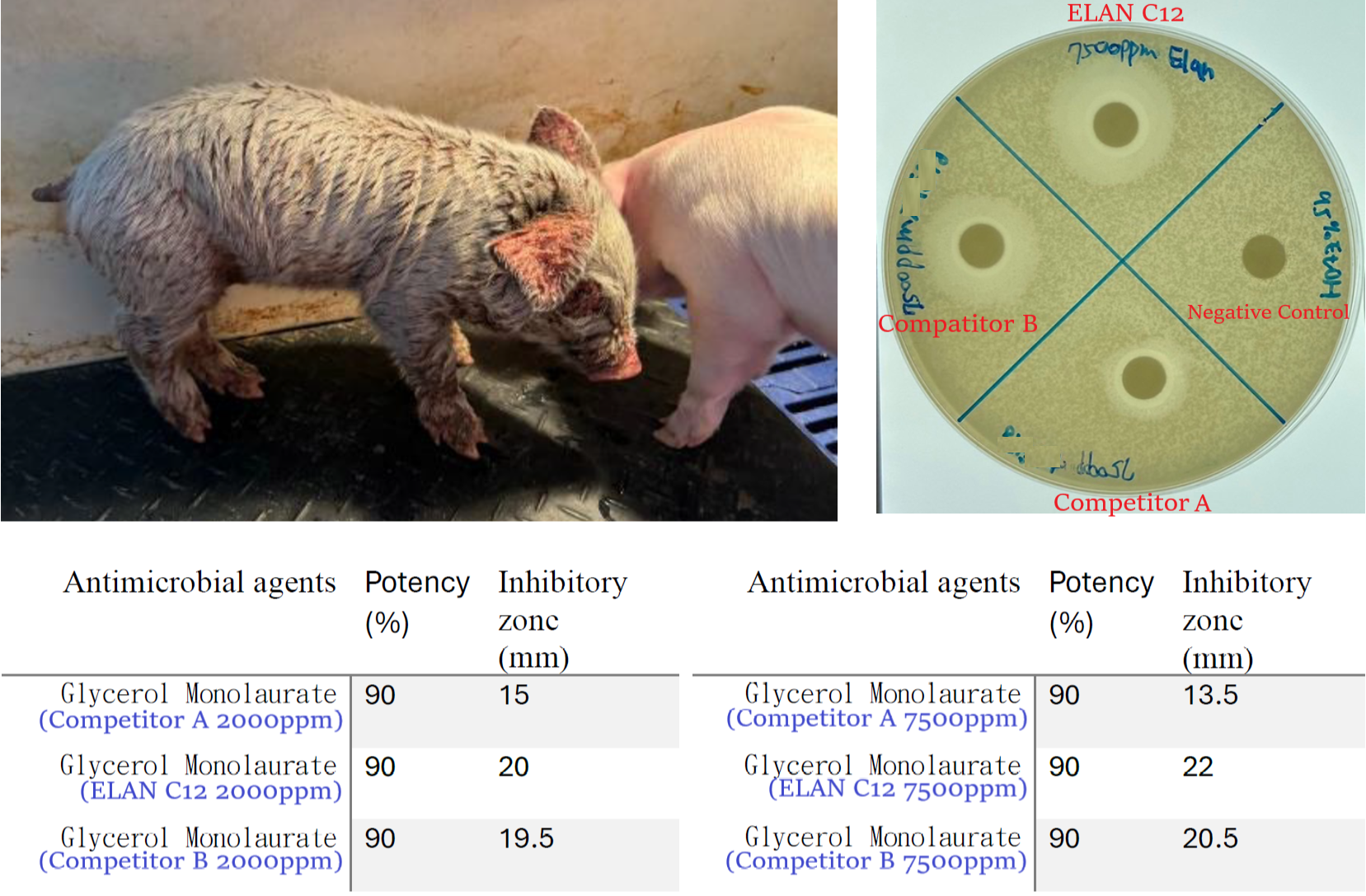

Our process for selecting raw materials is rigorous. First, we rely on our in-house laboratory and R&D team to test new samples thoroughly. We understand what the final users care about most, and this allows us to choose testing criteria based on real issues faced in farming environments. We also stay informed about what our competitors are doing, ensuring that our products meet or exceed industry standards.

(The affected pigs exhibited reduced appetite, rough and elongated hair, and reddened skin covered with dry, cracked scabs formed from greasy exudate. Preliminary microbiological examination identified Staphylococcus as the cause. Staphylococcus isolated from the pigs' lesions were used as the target for this inhibition test. The trial compared two competitor products provided by the farmer, along with BiomiXin’s selected product, Elan C12. All three products contained 90% glycerol monolaurate. The analysis was conducted at four concentration levels, ranging from 1000 ppm to 7500 ppm. The results showed that Elan C12’s antibacterial effect was comparable to Competitor B and significantly better than Competitor A.)

Before making any decisions, we assess the supplier’s facilities and review their manufacturing processes in detail. Rather than simply opting for widely available materials based on price, we focus on sourcing ingredients with unique advantages and superior processing methods.

Product Development: Real-World Examples

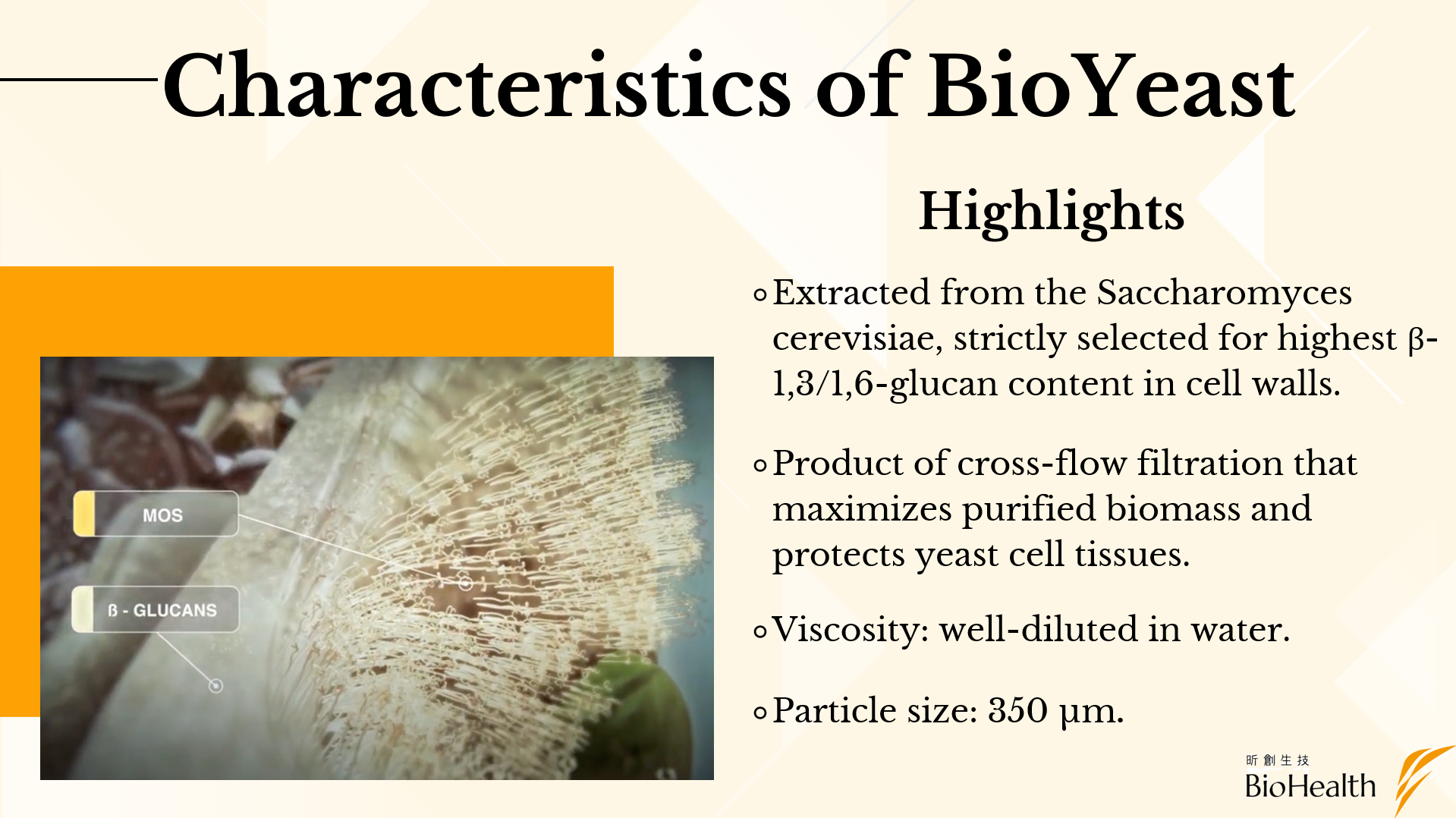

Take, for example, our recent development of α-monolaurin and hydrolyzed β-glucan. While these ingredients are not new to the industry, our processing methods set them apart. The unique esterification of α-monolaurin makes it 200 times more effective than standard lauric acid in combating gram-positive bacteria and viral with envelope. Similarly, our hydrolyzed β-glucan is protein-free and offers the highest concentration of β-glucan on the market, significantly enhancing its bioavailability and active properties.

Ensuring Quality through Training and Trials

We ensure that every new ingredient is fully understood by our sales team, offering comprehensive training on its benefits and applications. Additionally, we conduct real-world trials with loyal customers, using their feedback to validate our products and refine our processes. This cycle of continuous improvement helps us stay on the cutting edge of innovation, while also meeting the practical needs of our customers.

Through these steps, we’re not just trading ingredients—we’re optimizing them, delivering real value, and driving growth in the industry.